OAKLAND — Fans of comic book superhero Iron Man know that the man who wears a high-tech armored suit to battle evil is named Tony Stark, played in the hit movie franchise by actor Robert Downey Jr.

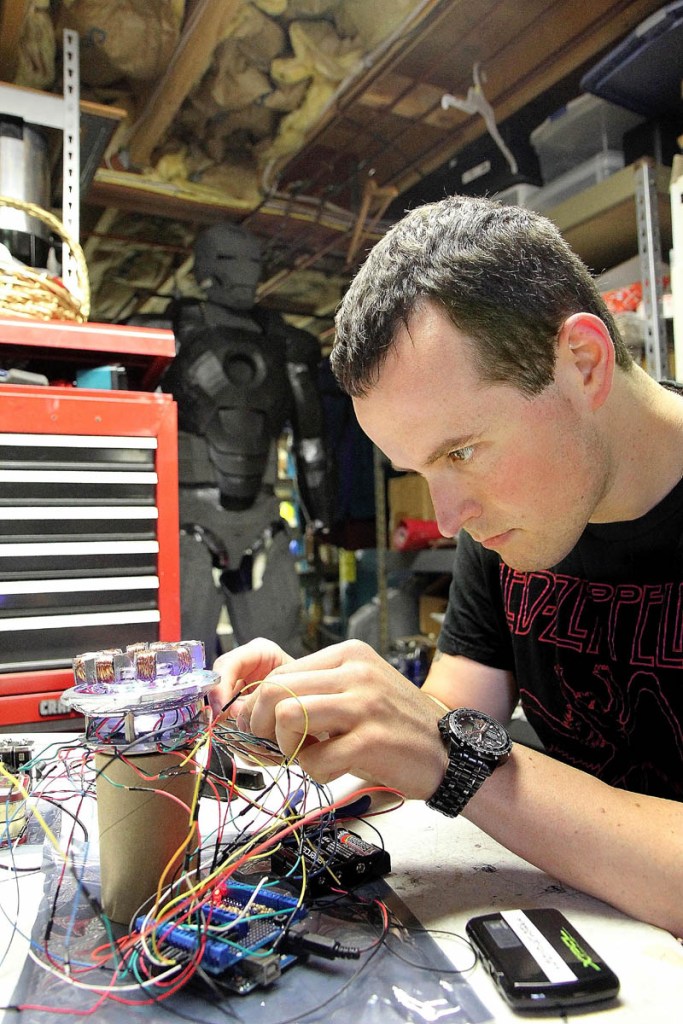

But when people see Iron Man walking around Oakland this fall, the man inside the armor is likely to be Thomas Lemieux, a mild-mannered, 28-year-old hospital worker who spent more than $2,000 and 400 hours building the elaborate costume in his basement.

Lemieux is an example of a “maker,” the tech-savvy tinkerers of a new generation who are using the Internet to take creative and oddball home workshop projects to a whole new level.

While he may not measure up to the fictional Stark, a self-described “genius-billionaire-playboy-philanthropist,” Lemieux does have some things in common with the character. Like Stark, he has a healthy interest in electronics, the confidence and perseverance to move his projects from the planning board to the workbench, and a tendency to work on his creations at all hours of the night.

The suit, made of sheets of foam rubber, won’t stop bullets, fly, or allow Lemieux to swing cars like a baseball bat. But it does come with some nifty gadgets.

A rotating circle of LED lights simulate a futuristic “arc reactor” in the chest, and Lemieux has preprogrammed a sound board that synthesizes his voice into a robotic approximation of the movie character. The sound board is also equipped with various audio clips, allowing Lemieux to evoke certain movie scenes or have brief conversations with supporting characters.

Lemieux said the most difficult challenge was the helmet, designed to open and close automatically with servo motors.

The suit’s gauntlets contain “repulsors,” beams of force that serve the dual purposes of allowing Iron Man to fly, and blast his enemies.

Lemieux’s repulsors, which light up and sound like the ones in the movie, are activated by a biometric system that reads the electrical impulses in his forearm. The effect is that, when Lemieux raises his palm, the repulsor is deployed.

Lemieux said he has dreamed about advancing his creation to the point that it would actually have some functionality. He’s seen one homemade suit online that comes equipped with a real laser, strong enough to burn holes in pieces of paper or pop balloons.

Jetpacks do exist that allow people to fly, he said, and some warehouse workers use metal exoskeletons to pick up pallets, like a forklift.

But generally, the technology is not small enough, streamlined enough, practical enough, or cheap enough for him to incorporate such elements into his suit — yet.

In the meantime, Lemiuex spends many of his waking hours either actively creating his suit, or thinking about it while working a night shift at MaineGeneral Medical Center’s Thayer campus as a sterilization technician.

On his work breaks, he sometimes carves a piece of foam into the next bit of armor. When he gets a good idea at work, he scribbles it down on a sheet of paper to take back to the multi-room finished basement of his father’s house, where he lives.

In the wee hours of the morning, Lemieux stays awake, cutting, gluing, painting, sanding, wiring and planning his way to achieving his dream.

Maine makers doing it themselves

Hardcore do-it-yourselfers like Lemieux are makers, a new word that gives a different spin to an old concept, according to Richard Sisco, of Skowhegan.

“A maker is a do-it-yourselfer, someone who will get their hands dirty for fun or for something they need,” he said.

The term maker was coined in 2005 by Dale Dougherty, co-founder of the California-based Make Magazine. The magazine sponsors “Maker Faires,” at which makers show off their creations — ranging from practical to artistic to whimsical — to the public. The first one, held in 2006 in San Mateo, Calif., drew 20,000 people, a number that has grown consistently during the last seven years.

Last year, the two largest Maker Faire events, held in San Francisco and New York, drew a combined 165,000 people.

Makers appear frequently in a vibrant network of websites, the biggest of which, called Boing Boing, ranks as one of the most popular blogs in the world with 3.5 million unique visitors each month.

In Maine, a group of about 50 people, including Sisco and Lemieux, have come together in an online forum to advocate for the founding of a local “makerspace,” essentially a community workshop. Sisco said Waterville is an ideal location for such a space, because of its easy access to Interstate 95.

Right now, even without a makerspace, Sisco and other group members are engrossed in their own projects, which include a large stained-glass moth, an etching machine, two wheelchair-based robots and a remote-controlled “quadcopter,” with self-stabilization capabilities and a built-in GPS system.

Sisco himself is building one of the robots, which he said he will connect to a lawnmower and a navigation system that will allow it to mow his lawn, among other things.

A makerspace would help group members to pool both resources and inspiration, Sisco said. For example, Sisco could house his welder there for use by other makers, while he could use their tools for his own projects.

In months of online discussions, the idea has attracted a lot of support, but little in the way of concrete plans.

“We’re in that stage where we’re getting ready to get off our butt and do something,” Sisco said.

The transformation

Sisco said Maine’s maker community is lagging behind those in other states, but that it has been growing steadily over the past three years. In September, Maine will host two Mini Maker Faires of its own.

The first, at the Camden Public Library on Sept. 7, will feature underwater robots that can be built for $60, a bicycle-powered ice cream maker, and space suit gloves, among other projects. Organizers of the second event at the Museum L-A in Lewiston-Auburn, have not yet released a list of the 20 scheduled participants. But at last year’s inaugural event, 17 makers from around the state showed off things including a robotic basketball game, self-inflating puppets, and a hand-made windmill.

The difference between makers and old-school putterers can mostly be chalked up to the Internet, which has made it easier for people to share designs and feed each other’s creative fires.

In his quest to build Iron Man, Lemieux said he’s interacted with hundreds of people online to gather and share information, including posting questions in forums, watching online tutorials, and scanning hundreds of other projects for ideas.

As he builds, he improvises when he wants to, adding his own little twists that might be seen as improvements and emulated by others doing similar projects.

His experience demonstrates another central tenet of the maker community.

While makers transform raw materials into finished projects, they themselves are transformed into more capable problem-solvers by the experience of making.

For Lemieux, his whole vocabulary has been upgraded as a result of his desire to bring a superhero to life.

“I didn’t know a whole lot about voltage regulators and capacitors, resistor codes,” he said. “But I did my homework, so to speak.”

The big project had a small beginning. Lemieux first set out to build a replica of Iron Man’s arc reactor. When researching that project online, he was exposed to the range of possibilities, which inspired him to upgrade his plans.

Iron Man of Maine

Lemieux said he has a couple of dates planned to show off his Iron Man suit, but he’s not sure what its long-term future will be.

In late October, he hopes to take first place in a costume ball at the Hawthorne Hotel in Salem, Mass., part of a wider downtown Halloween celebration that includes a psychic convention in a strip mall.

In early November, he will suit up at the booth of a friend at a gaming convention in the Augusta Civic Center.

And next July, he hopes to make an appearance at Comic-Con, a large comic book-themed annual convention in San Diego.

But by then, he will likely be focused on his next project.

Lemieux has another thing in common with the fictional Tony Stark. One of the biggest mistakes of Stark’s career was the creation of Ultron, a robot of fearsome intelligence that dedicated itself to wiping out all biological organisms, Terminator-style.

Building a costume of Ultron, who will be featured as the primary villain of the next superhero “Avengers” movie due out in 2015, might also be Lemieux’s next project.

Unlike Stark, however, Lemieux can be fairly certain that his creation will not turn on humanity, but will instead advance Maine’s maker community.

Matt Hongoltz-Hetling — 861-9287

mhhetling@centralmaine.com

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.