AUGUSTA — If you’ve voted in Maine, visited a supermarket or looked at a college brochure, then you’ve likely seen the work of J.S. McCarthy Printers.

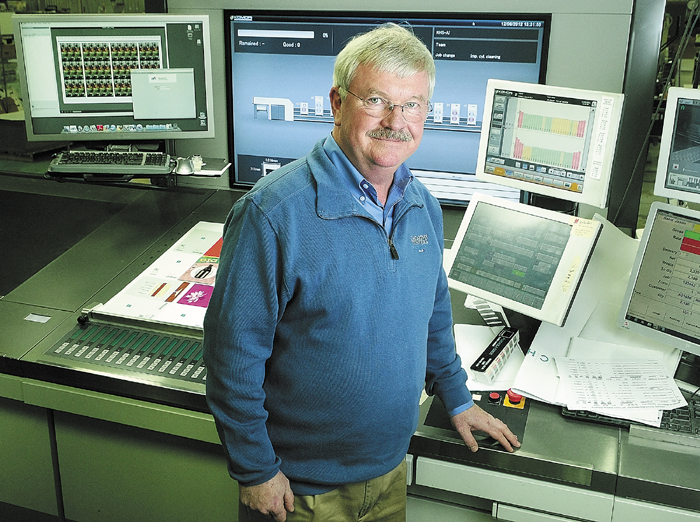

The Augusta-based company has established itself as a top printing operation in the northeast through investments in both technology and training, said Rick Tardiff, president and CEO. Besides its printing plant in the capital city, the company also has offices in Portland, Boston and Hartford, Conn.

J.S. McCarthy is being given the Business of the Year Award at the Kennebec Valley Chamber of Commerce’s annual awards banquet Jan. 25 at the Augusta Civic Center.

Peter Thompson, president and CEO of the chamber, said J.S. McCarthy has done a standout job of investing in technology to better compete in New England, add and retain jobs, and has made a huge impact on the community.

When walking through the plant on Darin Drive, Tardiff pointed out the wide variety of products the company prints — stacks of raw paperboard that will be used to make boxes for potatoes adjacent to an even larger tower of paper that will shortly become stacks of magazines.

“We’ve become known as a leader in our industry for looking for what’s the next thing out there that’s going to revolutionize our industry,” Tardiff said.

Often, the company works directly with its vendors to help shape what the new technology will look like, he said.

The most notable recent investment has been a new printing machine that can print simultaneously on both sides of a 28-inch by 40-inch sheet of paper in one-quarter of a second. He said it was the first one in North America and the first with the specifications the company helped create.

Gov. Paul LePage visited the company in April to officially start the new printing press.

Over the last five years, J.S. McCarthy has replaced 14 printing presses with three printers, while still increasing capacity by 30 percent, Tardiff said.

The company has made around $10 to $12 million in capital expenditures in the last 12 years for technological investments, according to Tardiff.

The company increases the effectiveness of its investments by waiting to upgrade until technology makes significant enough jumps in performance to justify the expenditure, he said.

Tardiff also showed off the company’s assembly line of saddle stitch machines — machines that bind booklets with two staples. After upgrading models, J.S. McCarthy’s machines went from being able to do 3,500 items an hour to 14,000 an hour.

“That’s a game changer,” Tardiff said.

The company brought in $31 million in revenue this year and hopes to grow that to $40 million in five years, Tardiff said.

Besides trying to grow the company through increases in marketing and sales efforts, Tardiff said it has acquired four other printing operations since 2000 and may be looking for more.

J.S. McCarthy employs 175 people, 145 of which are in Augusta, and an additional 30 full-time equivalency of temporary employees each year, Tardiff said.

Technology has also helped the company serve out-of-state companies — 65 percent of its customers — by allowing clients to view and mark proofs online.

“We’re at the end of the road,” Tardiff said of the printer’s northern location, relative to its clients. “We need to be better than our competitors and lessen that distance.”

Another way J.S. McCarthy has been able to attract more business is with its environmentally friendly practices, like purchasing 100 percent of it electricity from wind power. Tardiff said Fortune 500 companies often look at the environmental impact of printing companies when choosing a vendor.

J.S. McCarthy’s waste management practices have also resulted in significantly more materials being recycled — around 170 tons of paper a month. The company more than doubled its production in the last 12 years while still reducing waste, he said, cutting down on the cost to dispose of the material.

“It’s just plain good business,” said Tardiff.

Paul Koenig — 621-5663

pkoenig@mainetoday.com

Send questions/comments to the editors.

Success. Please wait for the page to reload. If the page does not reload within 5 seconds, please refresh the page.

Enter your email and password to access comments.

Hi, to comment on stories you must . This profile is in addition to your subscription and website login.

Already have a commenting profile? .

Invalid username/password.

Please check your email to confirm and complete your registration.

Only subscribers are eligible to post comments. Please subscribe or login first for digital access. Here’s why.

Use the form below to reset your password. When you've submitted your account email, we will send an email with a reset code.